Asset and Operations Management Services

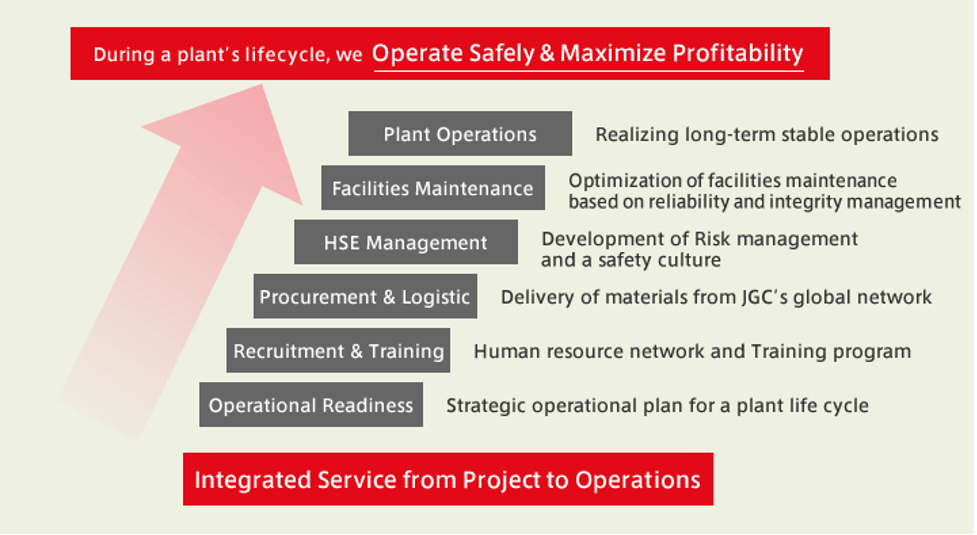

RAGNAR provides a full spectrum of services for asset and operations management, including operation and maintenance, human resources recruitment, training, management system development and on-site administration.

RAGNAR provides safe and stable operations for its clients through asset and operations management services and operational readiness throughout the FS, FEED, and EPC stages.

Facility Diagnosis

RAGNAR conducts inspections and diagnoses of existing facilities through nondestructive inspections and other means, and accumulate data to formulate optimal maintenance plans together with clients. Based on the know-how accumulated in the maintenance business, we have developed “A-MIS,” a state-of-the-art facility diagnosis system featuring predictive maintenance functions. The main services we provide are as follows.

- Consultation: support for the development of technical codes and standards, facility specifications, historical data and engineering data

- Nondestructive inspection: entire facility management including drafting an inspection plan for the facility, evaluating the results, executing the inspection, and drafting countermeasures

- Diagnosis: inspection and diagnosis of oil refining, petrochemical, chemical, and gas processing facilities in Japan and overseas

- Life evaluation: providing technologies for evaluating remaining life and safety based on materials, operation history and damage phenomena

- Investigation, analysis and assessment: inspection to identify causes of damage, and offer of measures or steps to be taken

- Maintenance and Diagnosis Management System: development and sales of advanced facility diagnosis system “A-MIS,” featuring predictive maintenance functions

Plant Maintenance

Mainly for refinery and chemical plants, we improve the economic efficiency and safety of our clients’ facilities through daily maintenance, shutdown maintenance and cleaning services. The main services are as follows.

- Daily maintenance: providing efficient maintenance services, taking into account factors such as safety, productivity, quality and cost

- Shutdown maintenance: proposing a plan that maintains safety and operational quality while reducing production losses

- Modification: providing optimal modifications by solving various problems that surface in the course of facility diagnosis

- Energy saving and capacity boosting: consultation on remodeling and refurbishment of facilities and equipment for energy conservation and capacity enhancement

- Cleaning services: establishment of various cleaning technologies essential to maintaining plant health and safety